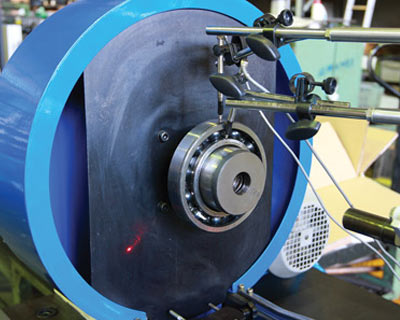

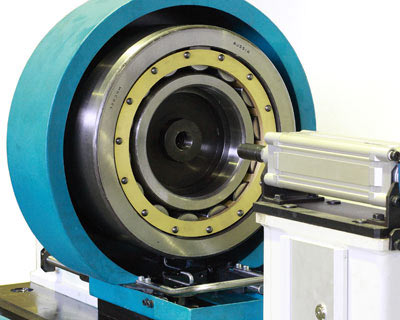

Roller Bearing Test Rig

SP-180M

SP-180M

| Type of bearings for diagnosis | ||

| Type of bearings | Type of load | |

| Radial load | Axial load | |

| Deep groove ball bearing (DGBB) (single and double row) | - | + |

| Self aligning ball bearing (SABB) | + | - |

| Angular contact ball bearing (ACBB) | + | + |

| Roller bearing with cylindrical rollers (single and double row) | + | - |

| Spherical roller bearing (SRB) | + | + |

| Roller bearing with conical rollers | + | + |

| |

||

| Technical Parameters | ||

| Inner diameter of controlled bearing, mm | 30 - 180 (220)* | |

| Outer diameter of controlled bearing, mm | 40 - 420 | |

| Width of controlled bearing, mm | 10 - 125 | |

| Sensors | 1 vibration sensor 1 temperature sensor 1 laser speed sensor 2 induction sensors |

|

| Frequency range of vibration sensor, Hz | 25 - 10000 | |

| Diagnosis speed, rev/min | 0 - 2000 | |

| The load exerted on the bearing, kg Radial Axial |

2.5 - 170 2.5 - 280 |

|

| The time of diagnosis of a bearing without time for installation, removal and heating bearing on the stand, min | 0.5 - 10 | |

| Amplitude of vibration acceleration control, m/s2 | 0.2 - 500 | |

| Power supply | 3 phase, 380 B | |

| Dimensions, mm | 1500 x 690 x 1450 | |

| Machine weight, kg | 380 | |

| * possible, control bearings with inner diameter exceeding 180 mm, provided that the outer diameter of less than 420 mm. | ||

DIAMECH 2000 Ltd.

Vibration Diagnostics & Balancing Machines

Vibration Diagnostics & Balancing Machines

Designed for validation of design data of roller bearings through actual testing at application loads and speeds by vibration characteristics, also allows to detect defects in the rolling surface, the separator and the geometric distortion on a new and repaired bearings.

Measuring System

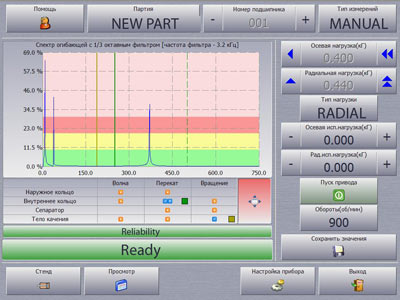

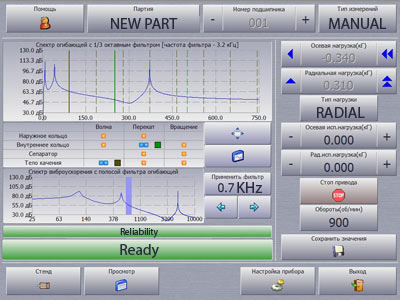

In the measuring system memory pre-installed data on the radial and axial test load, the required rotation frequency to desired bearing diagnosis. Based on these parameters, the operator adjusts the machine SP-180M and produces a bearing diagnosis.

| ■ | Vibration measurement |

| ■ | Vibration analysis (narrowband spectral analysis of vibration in three frequency bands of vibration and acceleration, analysis of the envelope and the envelope spectrum, excess and crest factor, direct spectrum vibration, velocity, acceleration, 1/3 octave and other filters. |

| ■ | Control of machine in the modes of acceleration, deceleration |

| ■ | Control of test load pneumatic cylinders |

| ■ | Measuring the speed of rotation of bearing cages (optional) |

| ■ | Measurement of internal clearances in the bearings (optional) |

| ■ | Static processing of measurement results |

| ■ | Reports in MS Word format |

| ■ | Self-test function |

| ■ | Touch screen display |

| Measured Parameters | ||||

| 1 Band, Hz | 2 Band, Hz | 3 Band, Hz | Overall Level, Hz | |

| Velocity | 50 - 300 | 300 - 1800 | 1800 - 10000 | 50 - 10000 |

| Acceleration | 50 - 300 | 300 - 1800 | 1800 - 10000 | 50 - 10000 |