On-Line Monitoring System - RUBY-M

Monitoring, diagnostics and protection of main and auxiliary equipment

Monitoring, diagnostics and protection of main and auxiliary equipment

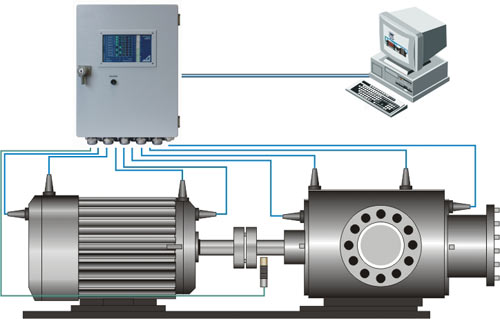

RUBY-M on-line system is designed for monitoring and thorough diagnostics of rotating equipment by vibration, temperature, current and other process and operating parameters.

RUBY-M system is represented by a combination of transducers (vibration, rpm, temperature, current, pressure, etc.) that have cable connections with multichannel measuring units.

Each measuring unit can function independently or within a uniform structure with distributed architecture bound with Ethernet network. The units are designed as modules and perform measurement by up to 32 independent channels (dynamic, parametric, tachometer, etc.).

Flexible combination of various types of channels with different sampling capacities as well as channels for synchronous (parallel) vibration control in real-time mode, all built within one unit, ensures best adaptation of measuring capabilities of the system to protection, monitoring and diagnostics solutions for different types of rotating equipment.

The system incorporates special control algorithms for evaluation of operating status of assemblies with rotating bearings. Individual measuring units or the system in whole can function in a fully standalone mode providing a real-time protection of equipment on a hardware level and generating alarms if controlled parameters go beyond allowable settings.

RUBY-M system is represented by a combination of transducers (vibration, rpm, temperature, current, pressure, etc.) that have cable connections with multichannel measuring units.

Each measuring unit can function independently or within a uniform structure with distributed architecture bound with Ethernet network. The units are designed as modules and perform measurement by up to 32 independent channels (dynamic, parametric, tachometer, etc.).

Flexible combination of various types of channels with different sampling capacities as well as channels for synchronous (parallel) vibration control in real-time mode, all built within one unit, ensures best adaptation of measuring capabilities of the system to protection, monitoring and diagnostics solutions for different types of rotating equipment.

The system incorporates special control algorithms for evaluation of operating status of assemblies with rotating bearings. Individual measuring units or the system in whole can function in a fully standalone mode providing a real-time protection of equipment on a hardware level and generating alarms if controlled parameters go beyond allowable settings.

Controlled Equipment

| ■ | Steam and gas low capacity turbines |

| ■ | Centrifugal compressors |

| ■ | Petrochemical production equipment (compressors and pumps) |

| ■ | Metallurgy (powerful draught systems) |

| ■ | Coal mining industry (ventilation fans, pumps) |

| ■ | Gas compressor stations |

| ■ | Oil pump stations |

| ■ | Municipal engineering systems |

Features

| ■ | Multilevel alarm and warning system implemented on hardware basis |

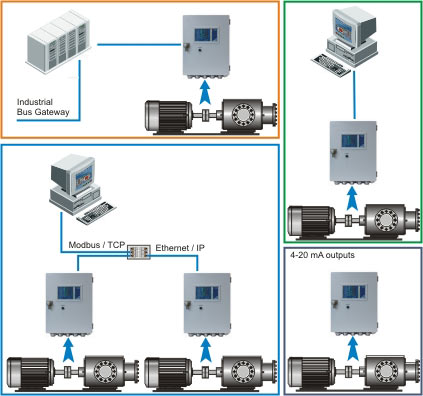

| ■ | Variety of technical solutions - possibility of working in a standalone mode, direct integration with automatic process control systems, establishment of distributed network architecture, etc. |

| ■ | Multifunctional measuring unit - combination of protection and diagnostics channels, use of up-to-date processor |

| ■ | Variety of input and output interfaces - possibility to connect practically any types of transducers (with rated 4-20 mA or 0-5 V outputs, sensors with IEPE interface, possibility to connect transducers via digital I2C interface), flexible integration |

| ■ | Immediate data control on hardware and software levels by means of built-in LED panel |

| ■ | Minimal cost - use of single PCB design for processing all of the signals |

| ■ | Easy installation and minimum length of cable connections - installation of measuring unit in proximity to controlled equipment |

| Technical Parameters | ||

| Functional capabilities: | Monitoring, Diagnostics, Protection |

|

| Controlled parameters: | Vibration, temperature, rotation frequency, current, pressure, etc. | |

| Connected transducers: | Piezoelectric accelerometers, microphones and velocimeters, MEMs vibration transducers, tachometers (proximity key), sensors with RS-485 interface, temperature sensors | |

| Number of measurement channels: (standard) |

8 synchronous standard analogue inputs 8 diagnostic analogue inputs (serial) 12 parametric analogue inputs I2C input (up to 27 sensors) 4 inputs for tachometer sensors |

|

| Sequence of channel scanning: | Combined (both parallel and serial channel scanning available) | |

| Vibration measurement | ||

| Types of measurements: | Any single- and multichannel measurements (general level, amplitude / phase, envelope spectrum, signal waveform, excess, peak factor, cepstrum, orbits, etc.), harmonic analysis | |

| Measurement parameters: · Frequency range · Dynamic range · Measurement error · Bandpass flatness · Sampling length · Spectral resolution |

2 - 25000 Hz up to 90 dB ± 5% ± 1 dB up to 1024K points up to 25600 lines |

|

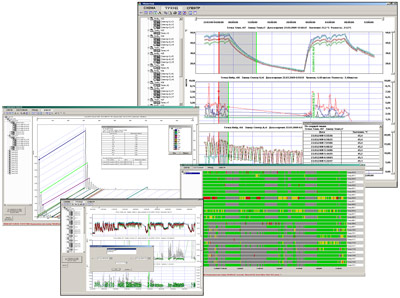

| Software | ||

| Software | AQUAMARINE-Monitor | |

| Automated diagnostics: | Optional (setup performed at system start-up procedure) | |

| Field balancing | Multiplanar | |

| Physical parameters | ||

· Display: · Body: · Modification: · Operating temperature range: · Power supply: · Power consumption: · Average time to failure: |

LED with linear dial All-metal IP67 (standard) -40 … +85°C (standard) 220 V, 50 Hz or DC 6 VA at least 100 000 hours |

|

DIAMECH 2000 Ltd.

Vibration Diagnostics & Balancing Machines

Vibration Diagnostics & Balancing Machines

Extensive connectivity

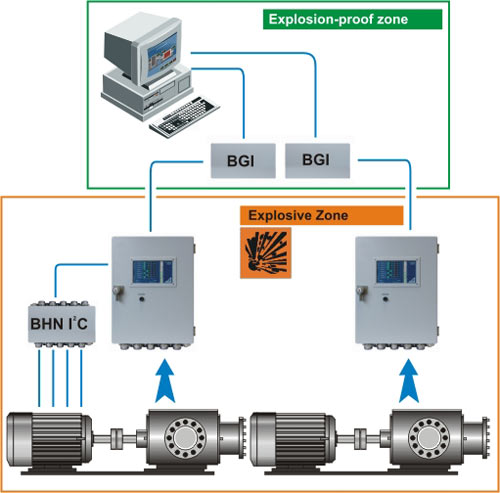

Explosion-proof construction

Powerfull Software

Monitoring, protection and thorough diagnostics of rotating equipment by vibration, temperature, current and other process and operating parameters.