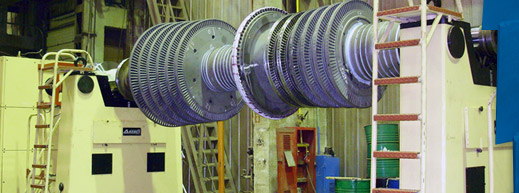

Transportable Balancing Machines for Steam Turbine Rotors

BM-25000, BM-36000, BM-65000, BM-90000, BM-127000

BM-25000, BM-36000, BM-65000, BM-90000, BM-127000

Universal soft-bearing balancing machines for highly precise balancing of a gas turbine rotors and steam turbine rotors with masses up to 127 tons.

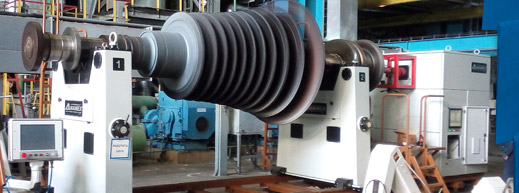

Balancing machines DIAMECH 2000 can be equipped with a special device for turning and grinding machining rotors. Now all the works on rotors repair can be performed on-site.

Since 1989, DIAMECH is the monopoly supplier of balancing machines in Power Energy of Russia.

Balancing machines DIAMECH 2000 can be equipped with a special device for turning and grinding machining rotors. Now all the works on rotors repair can be performed on-site.

Since 1989, DIAMECH is the monopoly supplier of balancing machines in Power Energy of Russia.

Features

Balancing Machines BM Series

High-Precision Balancing for Gas and Steam Turbines

Steam Turbines On-Site Repairs

Steam Turbines On-Site Repairs

Home \ Balancing Machines \ Horizontal Soft-Bearing Balncing Machines \ For Steam Turbine Rotors

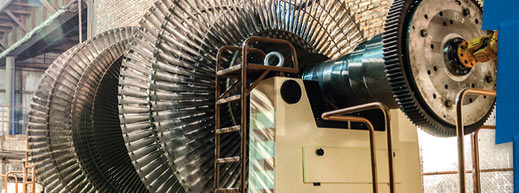

Highest balance sensitivity - up to 0.1 g·mm/kg. This balancing machines sensitivity is unattainable for many others manufacturers

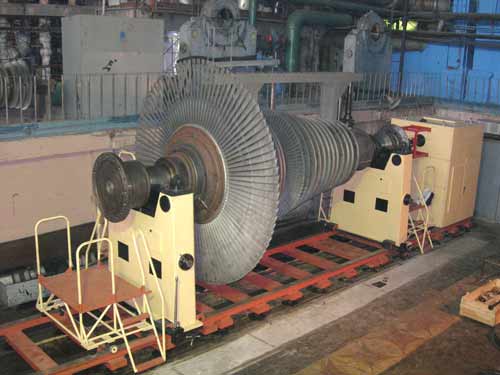

The machine installed without foundations, not required expensive construction of special concrete foundations

Anti-friction bearing work supports eliminate time-consuming alignment procedures. Bearings have a flat, wide-contact surface to carry rotors without damaging journals

High-precision balancing at lower and safer balancing speeds

Special automated complex PTSH-40 for turning and grinding operation for processing the surfaces of the rotor with special device to control the beating of the rotor for balancing machine >>>

A special device to control the beating of the rotor

Additional belt drive for medium weight rotors

All balancing machines DIAMECH 2000 is transportable and can be used when mounted on nearly any surface that will support its weight

Easy set up for new rotors

All balancing machines BM series supplied with newest measuring system SAPPHIRE-3 based on industrial touch-screen PC

DIAMECH 2000

Vibration Diagnostics and Balancing Machines

Vibration Diagnostics and Balancing Machines

Transportable Balancing Machine with Machining Attachment being used as part of a major overhaul of

Turbines on a Power Station

Manual and Automatic control

Mounted on the machine base